PRODUCT

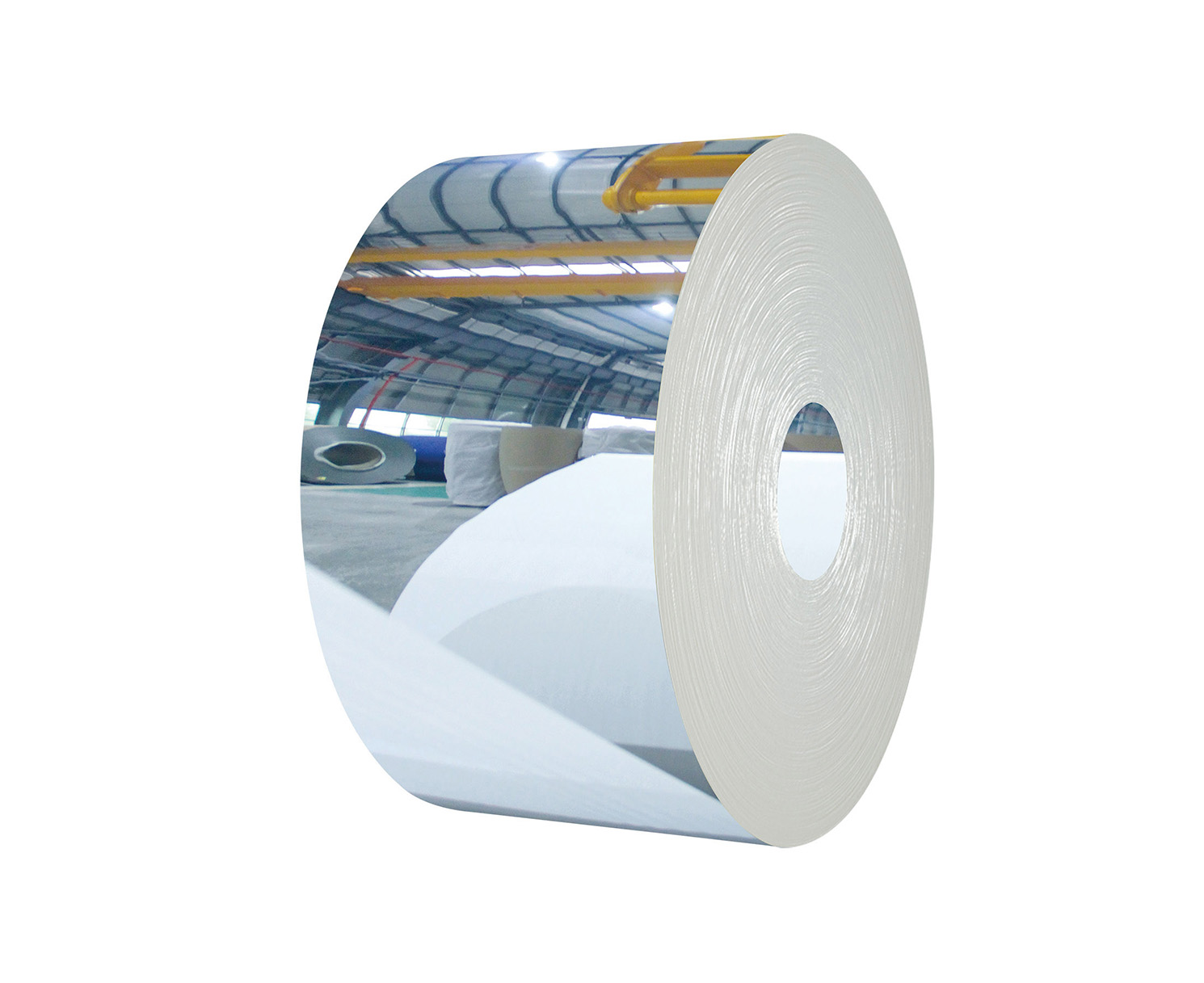

Mirror 8K

View Details

Surface Overview:

The mirror surface is achieved by using a cold-rolled 2B surface or a BA polished plate surface in a whole roll processing mode, and grinding and polishing to achieve a smooth surface. The product is divided into precision polished mirror and ordinary mirror.

Process Route:

Raw material NO.2B/BA - whole roll 8K polishing processing - roll/board finished product

Covering Steel Grade:

201J1、201J2、201J5、304

Surface Type:

Ordinary mirror surface (ordinary 8K), finely ground mirror surface (fine 8K)

Frosted Wire Drawing

View Details

Surface Overview:

Using cold-rolled 2B surface or BA polished plate surface, different sand surfaces are obtained by grinding the surface using a combined sand belt machine in a whole roll processing mode. The products are divided into snowflake sand surface, snowflake brushed surface, ordinary sand surface, etc.

Process Route:

Raw material NO.2B/BA - whole roll sanding processing - finished roll/board

Covering Steel Grade:

200 series, 300 series, 400 series

Surface Type:

Snowflake sand, Snowflake sand+brushed, Snowflake sand+plain sand+brushed, Snowflake sand+plain sand, plain sand, plain sand+brushed

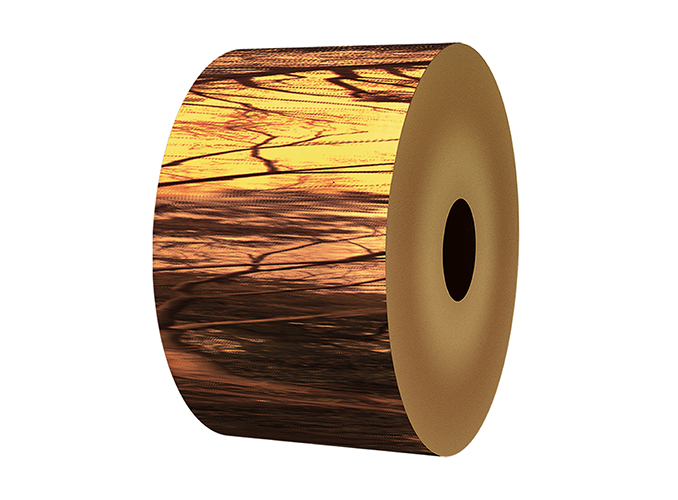

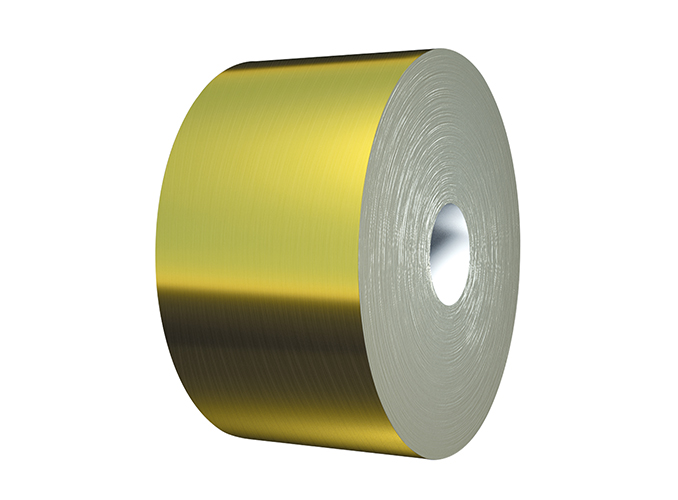

Mirror 8K Color

View Details

Surface Overview:

Based on the 8K mirror, in a vacuum environment, inert gas glow discharge and magnetron target sputtering technology are used to color process the surface or use a water plating series to process color plate products. Common colors include mirror rose gold, mirror titanium gold, mirror brown, mirror champagne gold, mirror black titanium, and other color steel.

Process Route:

1. Raw material 8K mirror surface - physical coloring line - roll/board finished product; 2. Raw material 8K mirror surface - chemical coloring line - roll/board finished product

Covering Steel Grade:

200 series, 300 series, 400 series

Surface Type:

Mirror colored series including mirror black titanium, mirror titanium gold, mirror rose gold, mirror champagne gold, mirror brown, etc

Wire Drawing Color

View Details

Surface Overview:

Based on grinding the sand surface with a sand belt, in a vacuum environment, inert gas glow discharge and magnetron target sputtering technology are used to color process the surface or use a water plating series to process color plate products. Generally, color steel is divided into rose gold, titanium gold, brown, champagne gold, and black titanium.

Process Route:

1. Sandbelt grinding sand surface raw materials - physical coloring line - roll/board finished products; 2. Sandbelt grinding sand surface raw materials - chemical coloring line - roll/board finished products

Covering Steel Grade:

200 series, 300 series, 400 series

Surface Type:

Sand surface black titanium, sand surface titanium gold, sand surface rose gold, sand surface champagne gold, sand surface brown, and surface anti fingerprint series (various sand surface combinations).